Maintenance of a generator is relatively similar to that of a car engine; it is similar to that of a car engine. It is essential that you adhere to the maintenance schedule that each generator manufacturer recommends for each type of generator. It is important to perform a routine maintenance practice, called an inspection.

Inspections include checking for leaks, checking oil and coolant levels, and checking the connections between the generator and the battery.

It is important to check the oil as well, as it must be changed on a regular basis. Oil changes should be done as recommended by the manufacturer, depending on how often your generator is used and what your work environment is.

It is recommended that you change the oil every 100 hours that the generator is in use.

Check the power of the batteries – power failures can happen to any generator if it has batteries that aren’t fully charged. Make sure that your batteries are robust and charged enough to last a long time, so that your generator will not start up unexpectedly.

Regularly checking to see if a battery is healthy and if it is failing. Test your battery by measuring the level of the battery acid and its specific gravity. You should make sure that the batteries are clean as well.

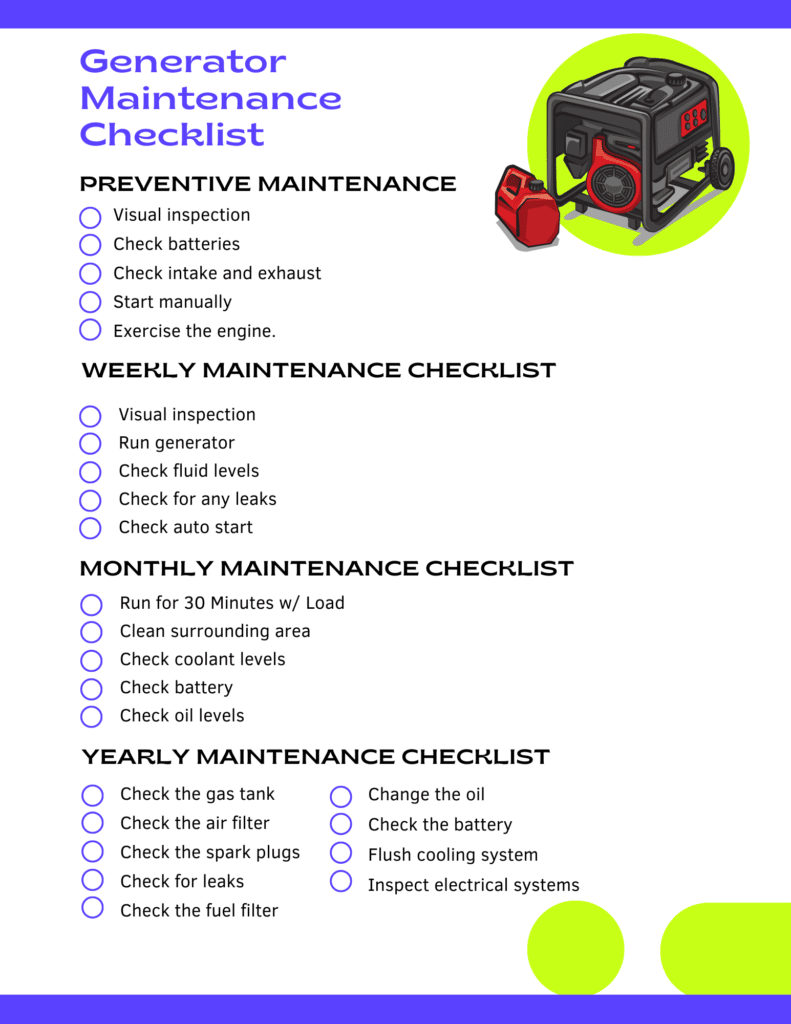

Generic generator maintenance checklists help you identify the parts that should be checked and when to check them so that you can keep the generator running smoothly when you need it most.

Fortunately, with proper maintenance, a generator can last up to 20 years. It also depends on how often you use the generator.

Without proper maintenance, generators are prone to problems such as fuel leakage. This can cause a generator to stop working and even cause it to quit running. Regularly maintaining your generator is as important as driving your car every week around town.

Generator Maintenance

It good to inspect your generator before every use, and keep a maintenance schedule that includes weekly, monthly, and annual maintenance checks.

If you regularly keep your generator maintained, it will continue to work safely and reliably for a long time, much longer than if you neglect to do the necessary maintenance checks.

1. Generator Maintenance – Weekly

When performing an inspection of a generator, whether it’s scheduled every week, every month, or every year, be sure there aren’t any oil leaks or other signs that the generator is starting to wear. It’s important to keep your generator clean by removing all traces of dirt and other debris from the inside of the generator, and to check that no pests have entered the engine.

To test the generator, check the fuel level and start the generator. If everything works correctly, run it for about 30 minutes.

It is important to inspect the exhaust system after starting the generator. Make sure there are no air leaks in the exhaust system and that the pipes aren’t overheating any neighboring parts by inspecting the muffler, manifold, and exhaust system. Make sure the engine is running smoothly by keeping an eye out for vibrations, smoke, or sudden drops in output.

2. Generator Maintenance – Monthly

Check the electrolyte level and battery cables once a month. Take off the plastic covers over the cell ports, and scrub them with a toothbrush and baking soda to get rid of any rust or grime.

Look for symptoms of coolant or oil leaks and make sure the engine’s oil level is near full but not overflowing. Make sure the coolant is a 50/50 mixture of distilled water and antifreeze. Antifreeze concentrations of up to 60% are permitted in areas where freezing temperatures are common.

Check for any problems by executing a load test of at least an hour on a monthly basis using a load bank. In addition, this is the time to undertake any specific gravity or electrical conductance tests on your electrolytes.

The frequency and duration of a generator’s use are critical considerations. Depending on how often you run the generator, you may need to alter the frequency of certain maintenance checks.

It’s recommended to change the oil after 100 hours of operation, albeit it should be done sooner on the first go-around. The first oil change should be performed after 30-35 hours.

Plugs and filters should be changed every 200-250 hours as well. However, if you store your generator and don’t use it frequently, you should empty the gasoline.

3. Generator Maintenance – Yearly

Once a year, pay attention to the electrical system of your generator. Turn off all power sources and perform an internal inspection. Check the internal wiring and alternator to make sure it’s free of dirt.

Check the air intake system to make sure it’s working properly, and if necessary, change the air filter. You need to make sure the air intake system on your generator is running properly, because that blows air into the generator’s crankcase to cause it to run smoothly.

Check that your switch on your generator is working properly, because this switch is needed to help you switch the power from the power grid to your generator when there is a power outage.

Some of the inspections and tests are more complicated, and more is at stake when you have a professional do them. Check the generator periodically and consider hiring a generator service company to do your annual inspection.

By using these weekly, monthly, and annual checklists, you can give your generator the care it needs. Taking good care of your generator will make it last for many years and help you to have peace of mind.

4. Preventive Maintenance

There are numerous moving parts in a power generator, including the control panel, batteries, and wires. In order to keep your generator in good working order, you should perform some preventative maintenance as well.

Recommended Read

- Best Ways to Make Generator Safe for Electronics

- Overheating Generator [Causes and Solution]

- Reasons Why Your Generator Won’t Start & What to Do

- How Long Can a Generator Run?

Generator Maintenance – How to’s

Why Is It Hard for My Generator to Start Up?

Having trouble getting your generator going after a lengthy period of inactivity is normal. Checking for external damage and broken parts that need replacing should be the first step in diagnosing a generator. The fuel tank or fuel filter may be full of old gas, the battery may be dead, the spark plug may be corroded, or the carburetor may be clogged.

What Should I Do if My Engine Falters?

When diagnosing a faltering generator engine, the fuel filter is often the source of the problem. If switching out the gasoline filter does not solve the issue, the carburetor could be to blame.

What Should I Do if My Engine Repeatedly Shuts Off?

If your generator’s engine suddenly shuts off while it’s operating, you should probably check the air filter first. If that’s not it, maybe your fuel filter is blocked, you don’t have enough gas, or your generator is overloaded.

Should I Put a Fuel Stabilizer Into My Tank?

As was previously noted, a generator should not be used as a gas storage tank. The use of a fuel stabilizer is recommended if you want to keep gas for your generator in a container. Please keep in mind that you should never keep gas in a closed container like a car or a house.

Why Is There No Electricity when My Engine Is Running?

First, make sure the thing you’re trying to power is working. Test if the problem persists by connecting it to another source you know is active. A tripped circuit breaker is another possible cause. If those are not the issue, a generator inspection by a professional will be required.

When a circuit breaker opens again as soon as the load is applied after being closed, it indicates that the load is excessive. The machine’s capabilities should be tested. Professional maintenance on your generator is required if you are operating within acceptable parameters but still experiencing frequent breaker trips.

Which Type of Oil Should I Put in The Generator?

The answer to this question will vary based on the requirements of the engine. Refer to your engine handbook for specific oil recommendations, but in general, high-quality 30-weight is fine for summer, and high-quality 10W-30 is fine for winter.

I Haven’t Used My Generator in A While; Should I Start It Up?

When it comes to routine maintenance for your generator, this is one of the simplest tasks you can perform. It’s smart to put some load on the generator every so often. In order to keep the gas from gumming up the carburetor, you should run the engine once a month.

How Can I Check the Oil Level?

Find the dipstick and pull it out. Find the oil line and the full mark on the dipstick to determine the level of oil in the tank. If the dipstick shows that extra oil is needed, add it up to that mark, taking care not to overfill. If you want to keep from having to do any more maintenance on your generator, it’s important to change the oil as per manufacturer instructions.

Is It Necessary to Drain the Gasoline from My Generator Before Storing It?

If you’re putting your generator away for an extended period of time, whether indoors or out, you should drain the gas tank. Storing flammable items inside a house is a bad idea for many reasons.

How Do I Switch out The Fuel Filter?

Although specific instructions may be provided by the manufacturer, most inline fuel filters are removed by closing the fuel valve, unhooking the clamps on either side of the filter, and pulling the old filter out of the line.

Be sure you can see light coming through by looking through the filter. If you can’t, you need to get a new one. Just follow the same steps in reverse to replace your fuel filter. An arrow on a fuel filter should point in the direction of fuel flow.

How Do I Replace My Air Filter?

You should include checking the air filter in your routine generator maintenance. While the specifics of when an engine’s air filter should be replaced will vary widely from model to model, the general principle remains the same: when the filter becomes clogged, the engine will either not get enough clean air or will have to work too hard to get the air it needs. You will find instructions on how to change the air filter in your generator by consulting the manual.

How Do I Get Rid of Old Gas in The Generator?

Make sure you follow the instructions in the manual. While some generators only need to have the old fuel emptied and the new fuel pumped into the tank, others require a full service, which includes replacing the fuel lines, filters, cleaning the carburetor and also the tank.

When Should I Change the Oil Filter?

Most manufacturers of generators advise replacing this component whenever oil is changed to prevent the new oil from being filtered through old contaminants and muck. Checking the handbook for your specific machine is a good idea, but replacing an oil filter is usually as simple as unscrewing the old one, pouring oil to the new gasket for lubrication, and putting on the new one.

How Do I Clean My Car’s Carburetor?

Carburetor cleaning is a more involved process that is best left to a professional mechanic. To get it off, you’ll need to disconnect the fuel line and sometimes the fuel tank, and a thorough cleaning will need disassembling the carburetor and spraying it with carburetor cleaner.

How Do I Perform an Oil Change?

Altering the oil in your generator is a part of routine maintenance. The easiest way to drain the oil and impurities from your generator’s engine is to run it for a few minutes to warm up the engine. You then take off the top of the oil pan and set it on an oil catcher.

Remove the old oil filter and replace it with a new one. Fill the engine with the oil specified by the manufacturer and turn on the generator once more.

After letting the generator run for a few minutes, you should switch it off and double-check the oil level. If you want to get the most out of your generator, this is one of the most crucial maintenance tasks you can do.

Where Should I Keep My Generator when I’m Not Using It?

Your generator should be kept in a safe, dry, clean area that is away from any sources of ignition. When putting generator away for the winter, it’s important to drain the gas and grease the spark plug holes.

How Can I Change the Battery?

If you have found that the problem is with the battery, you may be able to fix it by just doing a quick cleaning. If you notice that your batteries have corroded connections, turn off the engine and use baking soda, water and a soft brush to clean the contacts.

Cleaning your battery contacts is part of a regular preventive maintenance program. If your contacts are clean, but if your generator still won’t start, you may need to replace the battery.

Use a battery tester to check the state of your battery and see if it needs to be replaced. If you need a new battery, be sure that you purchase the right one. Check with the battery manufacturer’s website to find out what the manufacturer recommends. What do you do when you are ready to replace your battery?

- Turn off the generator.

- Unless you have cleaned your contacts, do it now.

- After you loosen the nut on the negative cable, remove it from the battery.

- Detach the positive cable from the battery.

- Take out the bar that holds the battery in place, and if necessary, replace the clamp or bar.

- Clean the battery tray.

- Place the new battery in the battery tray and place a bar or clamp to hold it in place.

- Spray a special spray on your battery terminals to prevent corrosion.

- Attach the positive cable and the negative cable to the battery.

- Secure all the nuts and bolts tightly

When Should I Change the Spark Plugs in My Generator?

It is not unusual for generator manufacturers to have different maintenance tips, but most say things like every 100 hours or once a year. You may need to change the spark plugs if they are worn or if they become cracked. Check to see if your spark plugs are old or worn – the spark plug is supposed to be replaced when the spark plug is worn out.

- Disconnect the wire from the spark plug.

- Clean around the old spark plug to prevent any contaminants from falling into it when you remove it.

- Use a spark plug socket to remove the spark plug from your generator.

Clean the spark plugs with spark plug cleaner and a wire brush to remove any debris. If there are any rust or cracks in the spark plug housing, you’ll need to replace the spark plug.

When replacing a spark plug, it is important that you follow the manufacturer’s specifications by measuring the distance between the electrodes. If you do that, your generator will continue to work for as long as it needs to. When you have the spark plug gap set to the manufacturer’s specifications, you can replace the spark plug and re-attach the wire.

Final Words

Although maintaining your generator is not as fun as actually using it, it is incredibly important to maintain it. A properly maintained generator will last for many years, giving you the power, you need to run your business. It will also ensure that you will never run out of power unexpectedly.

Keep in mind that you will need to do maintenance every time you use your generator, and if you store your generator for a long time, you will need to do it every time you start it up. If you wait until your generator stops working before doing any maintenance, it will be too late.