Generators come in a variety of shapes and sizes, as well as in terms of the external source, or mechanical energy, they are powered by. The definition of an electric generator is straightforward: a system that turns mechanical energy into electrical energy.

Electric generators are mostly used to provide backup power in the event of power outages, while they can also be used as the sole power source in mines and oil and gas drilling.

External sources, such as mechanical energy, are frequently used to classify generators. As a result, discussing diverse generators entails discussing different methods of electric power generation. So, what are the various types of generators and how do they differ? Let’s have a look.

Common Fuel Types for Generators Use

The following are the main fuel types for generators:

- Diesel – Most utilized fuel in industrial generators.

- Gasoline – Usually used for a short period of time on most potable generators

- Natural gas – More friendly to the environment than gasoline or diesel.

- Propane – Environment friendly fuel when natural gas isn’t an option.

There are a variety of other energy sources outside of hydroelectric dams and nuclear power plants, such as wind, solar, hydro (water), coal, and nuclear, all of which are used to generate electricity for the grid.

Hydrogen is primarily utilized in laboratories. Diesel, gasoline, or natural gas are the most common fuels used to generate power in buildings such as residences, companies, medical facilities, and hospitals.

Types of Generators available

Portable, standby, inverter, solar and industrial generators are all types of typical generators.

1. Portable generators

In the home or on a camping trip, portable units are often used to power important minor equipment. These generators, as the name suggests, are portable. Typically, they can run for between 7.5 and 12 hours on a tank of gasoline. We used the word “usually” because some can run for up to 24 hours straight.

It is important to note that the running time relies on the generator’s load, which relates to how much power it produces and what the generator is powering.

The fuel tank is housed within the generator. To use the generator, simply plug in your appliances or devices into the sockets built inside the unit’s frame.

Portable industrial generators, which can fulfill the same activities as commercial portable generators, are also available. They can run for less than 16 hours while simultaneously powering a number of appliances and can be transported anywhere. The size of these might vary. Some are too huge to carry, but can be loaded into a trailer and transported to a building site, for example.

Gasoline, diesel, or NG are the most common fuels for portable generators. Alternatively, some people use propane, which is more efficient in terms of energy use but also more cumbersome. As a result, propane is commonly utilized in caravans since it can run for a long period of time. As portable units lack sound isolation, they tend to be louder than stationary ones. This issue is being addressed by an increasing number of models currently available on the market.

2. Inverter generators

These are portable generators in the truest sense of the term, but they’re nevertheless considered to be in a category all their own. Inverter generators are in handy when trying to use a generator to power devices.

There are a wide variety of electronic devices that benefit from their use, but computers, microwaves, smartphones, and other delicate devices necessitate specific voltages and frequencies.

What is the working principle of an inverter generator? Unlike other portable generators, this one has a unique design. A high-frequency alternating current (AC) is generated by the engine. The alternator then converts it to direct current (DC). Generators are equipped with an inverter that converts the DC power back to AC.

Harmonic distortion is reduced due to these additional processes in generating energy and the fact that the starting AC frequency is high. In other words, the electricity is just as great as what you’d get from your local utility. Because of this, the generator is also more energy-efficient because it adjusts its voltage to match the exact voltage required by the associated load, neither more nor less.

The industrial inverter generator version of this popular home generator is also available for use in construction sites and other high-demand areas.

Inverter Generators – Pros & Cons

An inverter generator may be a good alternative for your off-grid electrical needs, but you must take into account all of the generator’s features and your individual scenario before making a decision. If you’re buying an inverter generator, here are some things to consider:

Inverter Generators – Advantages

- Low Noise Level – For the most part, inverter generators emit noise that is barely audible beyond a conversational level of 60 dB or less Because it runs more slowly and steadily, the little engine is quieter than a traditional generator. To reduce noise, inverter generators are built with an enclosed enclosure and sound-isolating mufflers.

- Cleaner Power – The electronic technology of the inverter creates a sine wave that emits significantly less emissions and produces significantly cleaner electricity than a typical generator. Electronics can operate more safely in a high-quality electrical output environment.

- Portability – Due to the smaller fuel tank, inverter generators are much more portable than traditional fuel-powered generators.

- Fuel Efficiency – When compared to traditional fuel-powered generators, inverter generators save a significant amount of money in fuel costs. Unlike a normal generator, an inverter generator dynamically adapts its engine speed to match the load, rather than a fixed speed. By reducing the generator’s speed, more fuel can be saved.

- Easy Maintenance – Conventional generators take a lot of time and money to maintain, but inverter generators require less upkeep. Maintaining the generator just requires battery inspection, that should be performed once a month to ensure that it operates as intended.

Inverter Generators – Disadvantages

- Price – The cost of an inverter generator is typically more than a standard portable generator. Although the unit’s initial price tag may seem prohibitive, the benefits it offers often outweigh the downsides.

- Lower Output – Because they are not as strong as bigger conventional generators, inverter power generators typically have outputs ranging from 2000-3500 watts to 9000 watts.. It is possible to run a few smaller home appliances, RVs, and other outside equipment with a basic inverter generator. The inverter generator can be used in parallel with a second generator to boost power production.

3. Standby generators

Defining a standby generator might be a bit of a stretch. These are usually, but not always, attached to the ground. They are more substantial than portable devices and may be used in both residential and industrial settings.

However, it’s worth noting that natural gas can be a concern. Natural gas pipes are generally shut off in the event of a natural disaster to prevent accidents.

The size of the fuel tank determines how long a diesel generator can run. Larger tanks are required for standby generators because of their size. Diesel-powered standby generators can run for three days or even longer periods of time.

A natural-gas generator is quieter than an open-frame or exposed diesel generator. Both generators can be placed in a noise-reducing enclosure. Small components like quarter-turn locks can assist keep generator noise from leaking out of enclosures, so don’t overlook them.

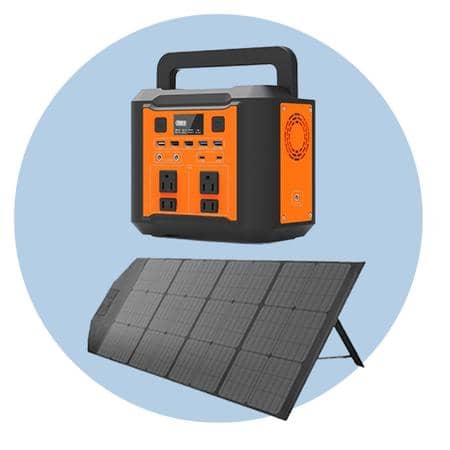

4. Solar Generators

It is quite expensive to install a whole-house solar power system, but the fuel it uses is renewable and cost-free. They are perfect for camping or storing in your truck as an emergency source of energy.

Typically, solar generators are equipped with built-in solar panels, but some are also equipped with detachable solar panels that may be positioned or slanted to better absorb the sun’s rays. Solar generators can be used to generate electricity for a variety of applications.

The downsides of these generators are that they do not function when it is dark outside and that they do not generate a great deal of power.

5. Industrial Generators

Industrial generators are what they sound like. A larger version of the standard standby generator. Power is needed for everything from robots, machinery, and lighting to datacenter in an industrial setting.

Therefore, they’re large-capacity generators that can provide a long-term, uninterrupted source of power. As a result, they has to be massive and powerful.

Industrial vs. Commercial Generators

These terms are frequently used interchangeably, however they are not the same. It is easy to recognize an industrial-scale generator when you see one. A large proportion of modern industrial generators is built with noise-suppressing components like heavy-duty vibration mounts that absorb shock and vibration.

Industrial generators can be found at power plants and some hospitals, as well as other places. Commercial generators are often not as large as industrial generators, and their applications and environments do not necessitate the same degree of power as industrial generators. Depending on their requirements, medical facilities and office buildings frequently make use of these generators.

Industrial Generators Types

This relates to the amount of mechanical energy utilized and the size of the generator. For example, as previously said, there are portable industrial generators, but these are not intended to perform the same function as huge, powerful generators. It is most common for industrial units to have diesel engine generators. There are also natural gas, gasoline, and hydrogen generators.

Read Next: